Industrial Grinding Inc. is a leading manufacturing company specializing in vertical grinding services. We serve many industries to support their expansive applications, ensuring we follow their project needs and specifications. Through our experienced employees, we can accomplish quality finished cylindrical parts and components that exceed your expectations.

What is Vertical Grinding?

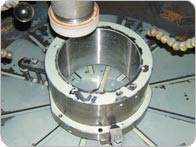

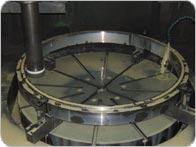

As the name suggests, vertical grinding is when the piece is held or mounted at the bottom of the machine, and the grinding spindle moves along vertically on the Z-axis on top of it. This configuration facilitates single set-up processing since it has an A-axis rotation, which means the grinding wheel rotates and can reach difficult places.

It also guarantees fewer distortions on the surface since mounting the workpiece requires less force, which reduces roundness errors. Additionally, it can complete outer diameter, inner diameter, and face grinding in one clamping process, ensuring that the circularity between the ID and OD is maintained more accurately with higher precision and consistency.

Other benefits of vertical grinding:

- Reduce set-up time: Certain models have automatic tool changers, which can store more grinding wheels within the machine. It shortens lead time so that we can meet deadlines.

- Unlimited cylindrical grinding operations: More flexibility means the wheel can grind away material as required while finishing.

- Increased life expectancy: Being selective with the grinding wheel can increase its life expectancy.

- More accurate results: With less set-up time and improved flexibility, vertical grinding can be more accurate with better results.

Extensive Applications of Vertical Grinding

Workpieces of large diameters and short lengths can benefit the most from our vertical grinding services. With this in mind, numerous demanding industries that require large components in their projects rely on our services.

Typical applications of vertical grinding include:

- Aerospace parts

- Large machineries

- Power Generation & Energy

- Oil Drilling & Refineries

- Large part components (Cylinders, Housings, etc.)

More industries with stringent requirements, such as the military and defense, also use our services. One primary reason is the consistency that vertical grinding offers, which is essential for their operations.

Finishing Quality Cylindrical Parts

Although vertical grinding is ideal for more significant parts, small vertical grinders also allow us to work on small cylindrical pieces. It enables us to grind and achieve custom products with a minimum inner diameter of up to 2″, depending on our client’s specifications.

Meanwhile, our large vertical grinders are fully equipped to work on high-performance parts with outer diameters of up to 67″. We focus on precision, high-speed, and fine and finish grinding operations. You can trust us to deliver results according to your requirements, such as customization options and chosen materials.

Typical tool steels we can handle:

- Stainless steel

- 4140

- A2, D2, & M2

- Chrome-plated surfaces

- Bronze

- Ceramic

- Tungsten Carbide

Depending on application and material type, we can manufacture superior components that need high surface finishes of up to 10-12 Ra (micro finishes). Our focus areas also help us achieve extremely tight tolerances and concentricity.

Choose Industrial Grinding Inc. to Accomplish Exceptional Parts

Our expertise allows us to deliver optimal outcomes that are second to none. With our fully-equipped in-house facility and team of expert operators, we can provide results that exceed your expectations.

If you want to know more about our vertical grinding services, don’t hesitate to contact us today. We can develop a cost-effective solution that’s tailored to your needs.